Centrifuge Technology

ETC’s gas centrifuge technology is by far the most efficient method of enriching uranium available.

ETC’s gas centrifuge technology is by far the most efficient method of enriching uranium available.

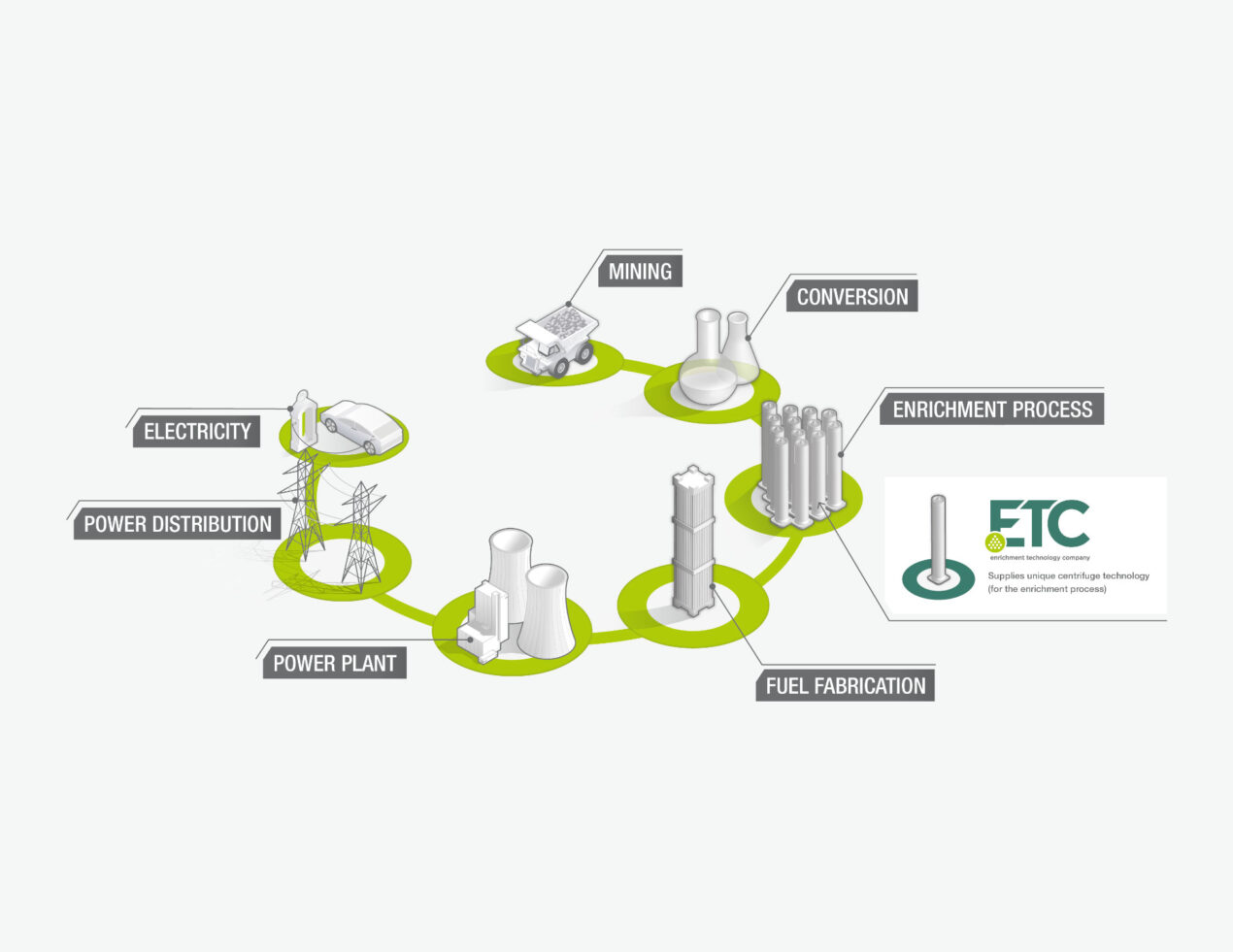

Before naturally mined uranium can be used as fuel, it must be enriched to the point where the concentration of one isotope, Uranium-235, is high enough for the fuel to be used in a nuclear reactor.

ETC’s gas centrifuge technology uses highly efficient centrifuges, rotating at high speed. Uranium, converted into a gas, is fed into the centrifuges where it is spun at high speeds. The centrifugal forces inside mean that lighter molecules move to the centre of the centrifuge, while heavier molecules move to the outside. This allows uranium gas with a higher concentration of the lighter molecule to be drawn off.

The process is repeated a number of times to increase the concentration, while depleted gas is drawn off to be recycled in the process. The gas passes through a number of centrifuges in series, known as a cascade. Once the desired concentration is reached, the uranium is processed back into solid form, where it can be transported to a nuclear power plant for processing.

ETC has developed a very efficient and reliable gas centrifuge technology, which has proven its effectiveness over many years of operation. Our technology is proven to be 50 times more energy-efficient than its main alternative, the gas diffusion process.

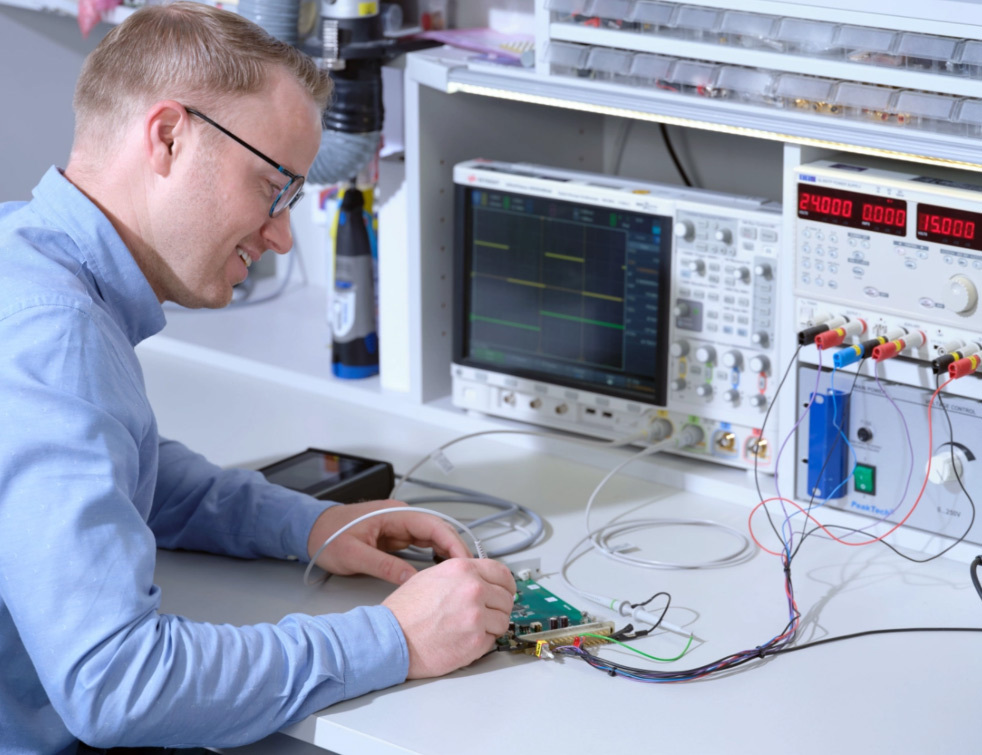

As a company ETC invests 20% of its annual revenue on Research and Development, putting us in the very top tier of companies worldwide for re-investment in innovation.

As a company ETC invests 20% of its annual revenue on Research and Development, putting us in the very top tier of companies worldwide for re-investment in innovation.