Nuclear Fuel Cycle

ETC’s Gas centrifuge technology is the world’s most efficient process for enriching Uranium to the point where it can be used as nuclear fuel for producing electricity.

ETC’s Gas centrifuge technology is the world’s most efficient process for enriching Uranium to the point where it can be used as nuclear fuel for producing electricity.

In its natural state, uranium two usually comprises isotopes, U-238 and the slightly lighter U-235. Natural uranium contains only around 0.7% U-235 and most nuclear reactors require a U-235 concentration of between 3% and 5%. The process of increasing the amount of U-235 is called enrichment.

Please select an area of the cycle to find out more

Uranium is mined as uranium ore, then milled, purified and concentrated. This produces uranium oxide (U3O8) commonly known in the industry as ‘yellow cake’ which is then transported to a conversion facility.

Milled uranium oxide is combined with hydrogen fluoride to form uranium hexafluoride (UF6). At room temperature, UF6 is a solid, and when heated it turns into a gas without going through a liquid state. Once converted, the UF6 is put into thick steel cylinders and moved to enrichment facilities.

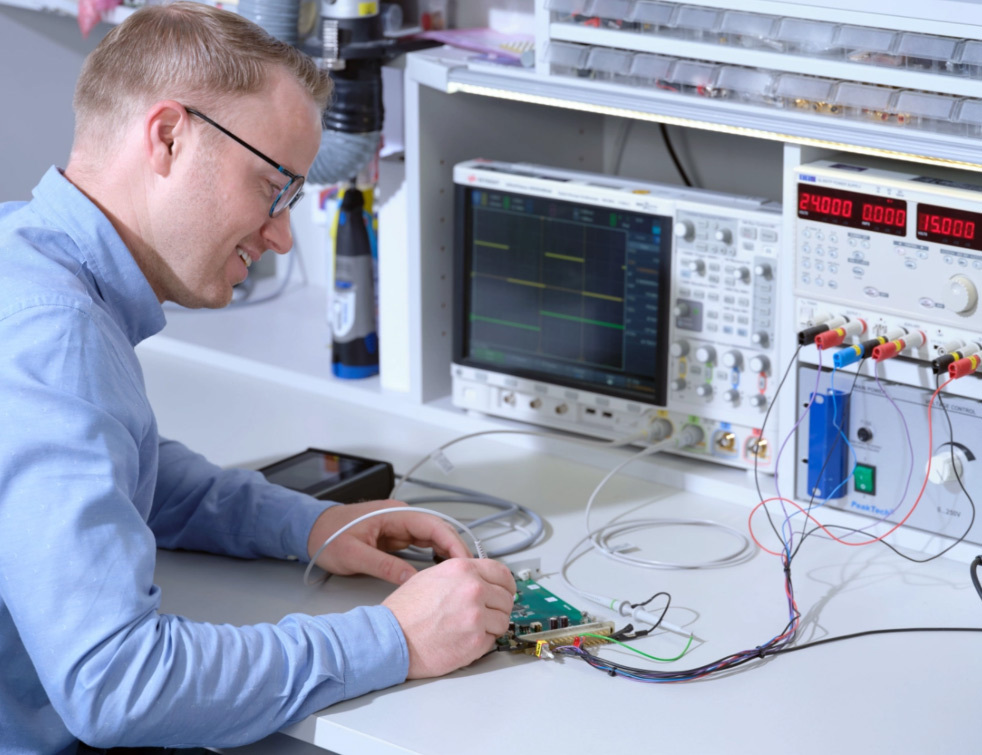

ETC’s gas centrifuge enrichment process uses a large number of rotating cylinders which are interconnected. UF6 is pumped into these cylinders, which use strong centrifugal force that draws more of the heavier gas molecules (containing the U-238) toward the wall of the cylinder, while the lighter gas molecules (containing the U-235) tend to collect closer to the centre. This enables ETC to increase the concentration of U-235 to the desired level.

The enriched UF6 is then chemically processed into powdered uranium dioxide (UO2). The powder is then pressed into pellets, which are loaded into pipes. These tubes are bundled into fuel rods and delivered to nuclear power plants.

The fuel rods are delivered to nuclear power plants where they are inserted into the core of the reactor. Heat generated by nuclear fission within the core is used to heat water to produce high pressure steam. This steam drives turbines, which in turn generate electricity.

The electricity produced is fed into a grid and distributed at high voltage. After the voltage is reduced, it is supplied to homes and businesses. The ever-increasing global demand for energy, coupled with the urgent need to address climate change by reducing and eliminating the use of fossil fuels, mean that nuclear energy is a key part of the mix of energy sources we need to provide a sustainable, low-emission future energy supply.

Electricity is essential for our society, and our demand for it keeps on growing every year. Electricity which is produced using nuclear fuel has a considerably lower carbon footprint than that used by burning fossil fuels such as coal, oil or gas. That’s why ETC believes that nuclear energy forms a vital part of the energy mix we need to create a sustainable low-carbon electricity supply for the future.

As a company ETC invests 20% of its annual revenue on Research and Development, putting us in the very top tier of companies worldwide for re-investment in innovation.

ETC has developed the world’s leading technology for uranium enrichment, gas centrifuge technology. The process uses centrifugal forces to enrich the concentration of one isotope of uranium. Our technology is by far the most efficient method of achieving this.